Description | |

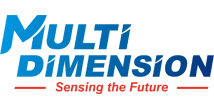

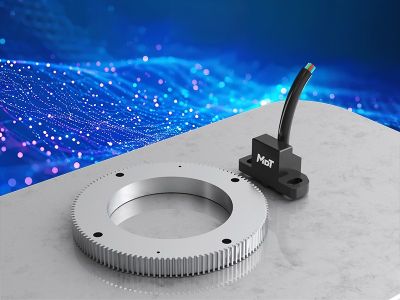

The GE-T geartooth encoders are non-contact incremental encoders measuring rotary speed and position in spindles and motors. Based on MultiDimension Technology (MDT)’s unique tunneling magnetoresistance (TMR) sensor technology, they detect changes in the magnetic field due to gear movement to achieve high sensitivity, fast response, high accuracy, and high reliability. |  |

Features and Benefits | |

Compatible: Incremental ABZ Signal Compatible: Incremental ABZ Signal |  Precision: High accuracy and high resolution Precision: High accuracy and high resolution |

Flexible: Customizable on demand Flexible: Customizable on demand |  Reliable: Designed for harsh environment Reliable: Designed for harsh environment |

Quick: High response frequencies, suitable for high-speed spindle Quick: High response frequencies, suitable for high-speed spindle | |

Applications | |

Spindles and motors Spindles and motors |  CNC machine tools CNC machine tools |

Energy and power generation systems Energy and power generation systems |  Elevators Elevators |

- Home

-

Products

- Sensor ICs

- TMR Switch Sensors

- TMR Angle Sensors

- TMR Linear Sensors

- TMR Gear Speed Sensors

- AMR Switch Sensors

- AMR Angle Sensors

- AMR Linear Sensors

- AMR Magnetic Scale Sensors

- Sensor Modules

- TMR Magnetic Image Sensors

- TMR Current Sensors

- TMR Geartooth Encoders

- AGV Magnetic Guide Sensors

- TMR Low Noise Linear Sensor

- TMR Flow Sensors

- USB Magnetometer

- Fabrication Service

- Demonstration Boards

- About MDT

- Technology

- Shop

- Contact us